HOME > ALL DISPLAYS > 1890-1915 > SHADE GUIDE

Shade Guide

1907 | Object #:A237.0002

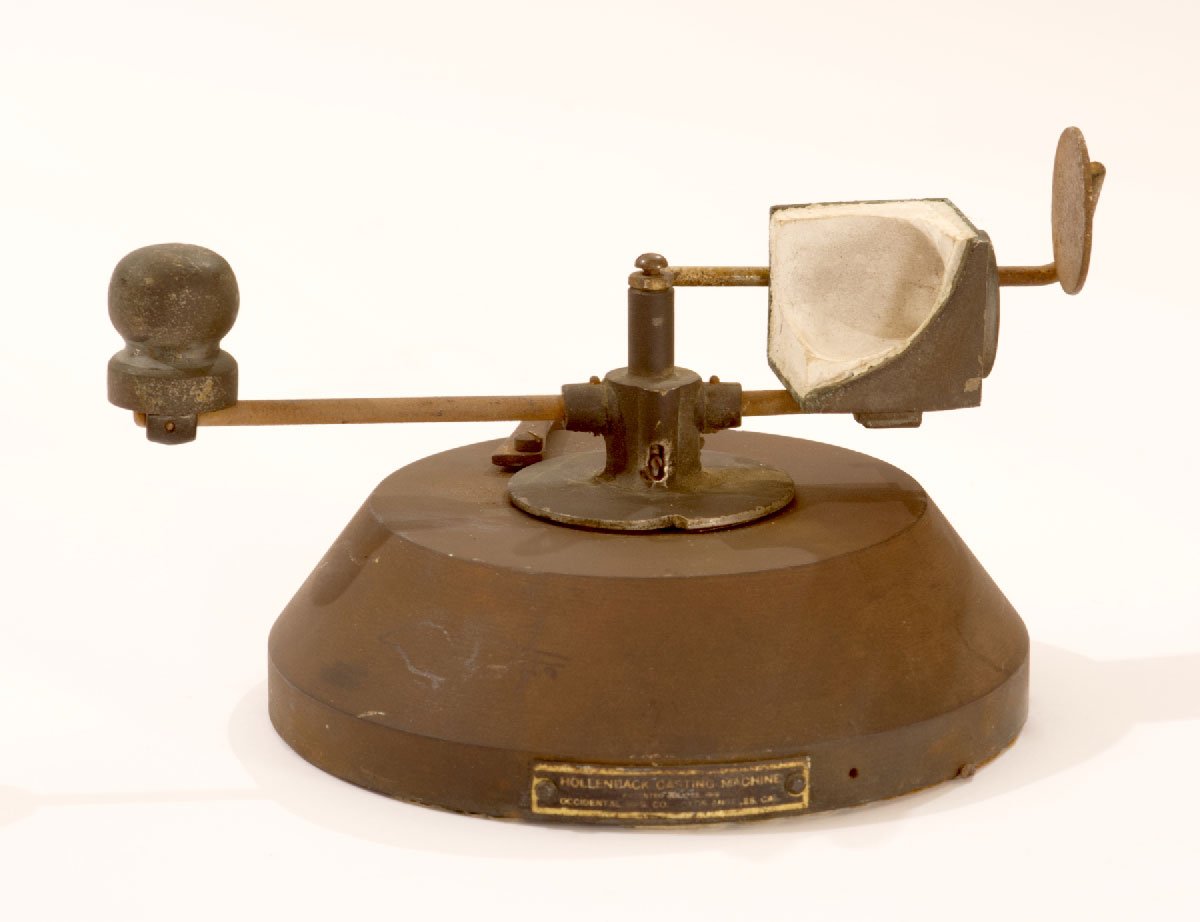

A cast inlay machine is a device used to fabricate dental prostheses such as crowns, fillings, and other dental inlays. William H. Taggart revolutionized the method for making inlay fillings and fixed partial prosthodontics with his Cast Inlay Machine. Following the centuries-old technique of lost-wax casting, this new machine was designed to hurl molten gold into a mold to create a more accurate gold casting. The mold was placed on the base platform. A gas flame supplied by the lower tube melted the metal in the casting ring at the base of the vertical plunger. The ring was lowered onto the mold with the wooden handle and compressed gas from the upper tube instantly forced the metal into the mold.

SCROLL TO LEARN MORE

Taggart’s first cast inlay machine used compressed air. Shortly after, he and others were looking for improvements to the casting process. It was not long before centrifugal force became the standard among most dentists.

1/9: Taggart’s mold was placed on the base platform. A gas flame supplied by the lower tube melted the metal in the casting ring at the base of the vertical plunger.

2/9: In Taggart’s version, a controllable nitrous oxide blowpipe unleashed the compressed gas instantly forcing the metal into the mold.

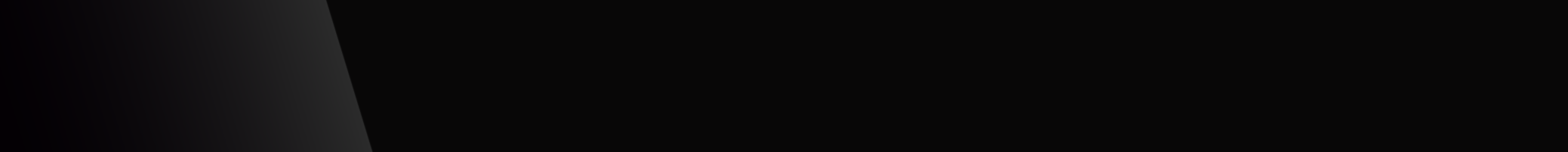

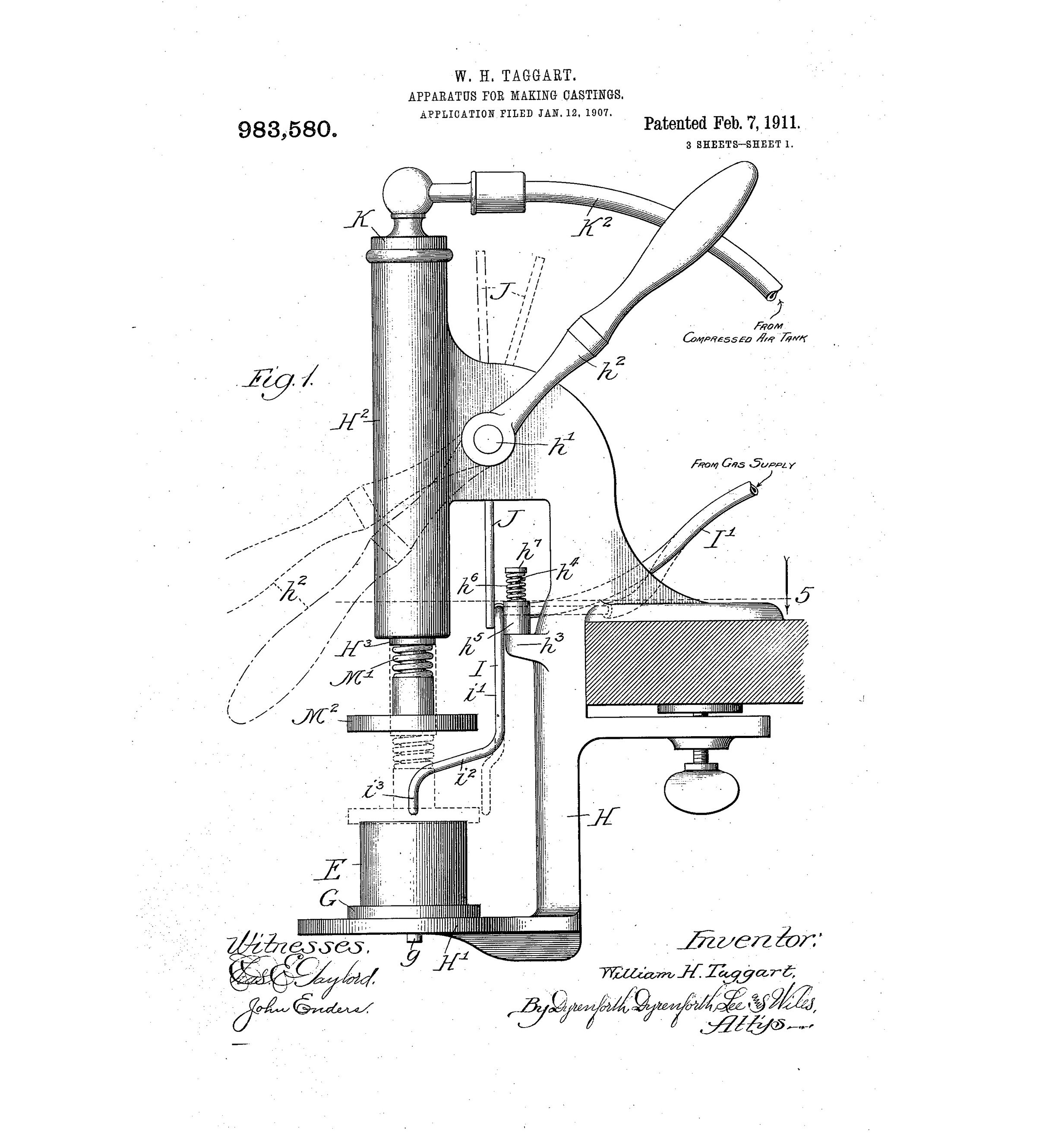

3/9: The Hollenback Centrifugal Casting Machine, patented in 1919 by Occidental Dental Manufacturing, created the pressure needed to fill the mold through rotation.

4/9: The ring of Taggart’s model was lowered onto the mold with the wooden handle and compressed gas from the upper tube instantly forced the liquid metal into the mold.

5/9: Figures showing how the wax mold is placed within the “investing” material which retains its shape so that liquid gold can be forced into the void.

6/9: Figures 1 and 2 show a wax mold that has been made of the missing area of the tooth. Figures 3 and 4 show the placement of a “sprue,” the spot in which the liquid gold will enter and fill the void left by the melted away wax.

7/9: A 1920 advertisement for the Hollenback Centrifugal Casting Machine.

8/9: An advertisement for cohesive gold foil from the late 1800s. Before the use of casting, gold foil would have been meticulously tapped into cavities – a tedious process that could take days.

9/9: Gold inlays made from modern casting methods.